Hog Salad Bait Molds

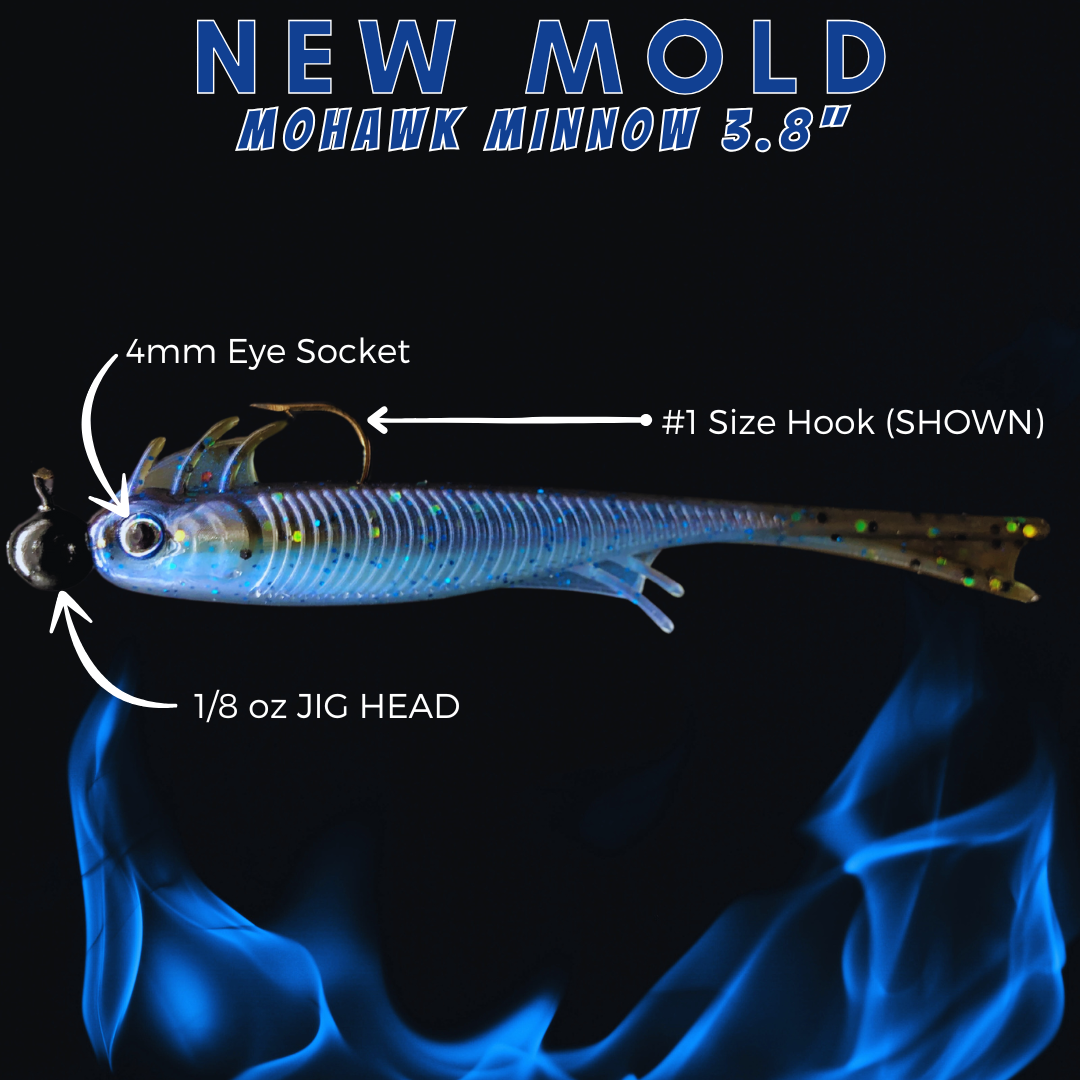

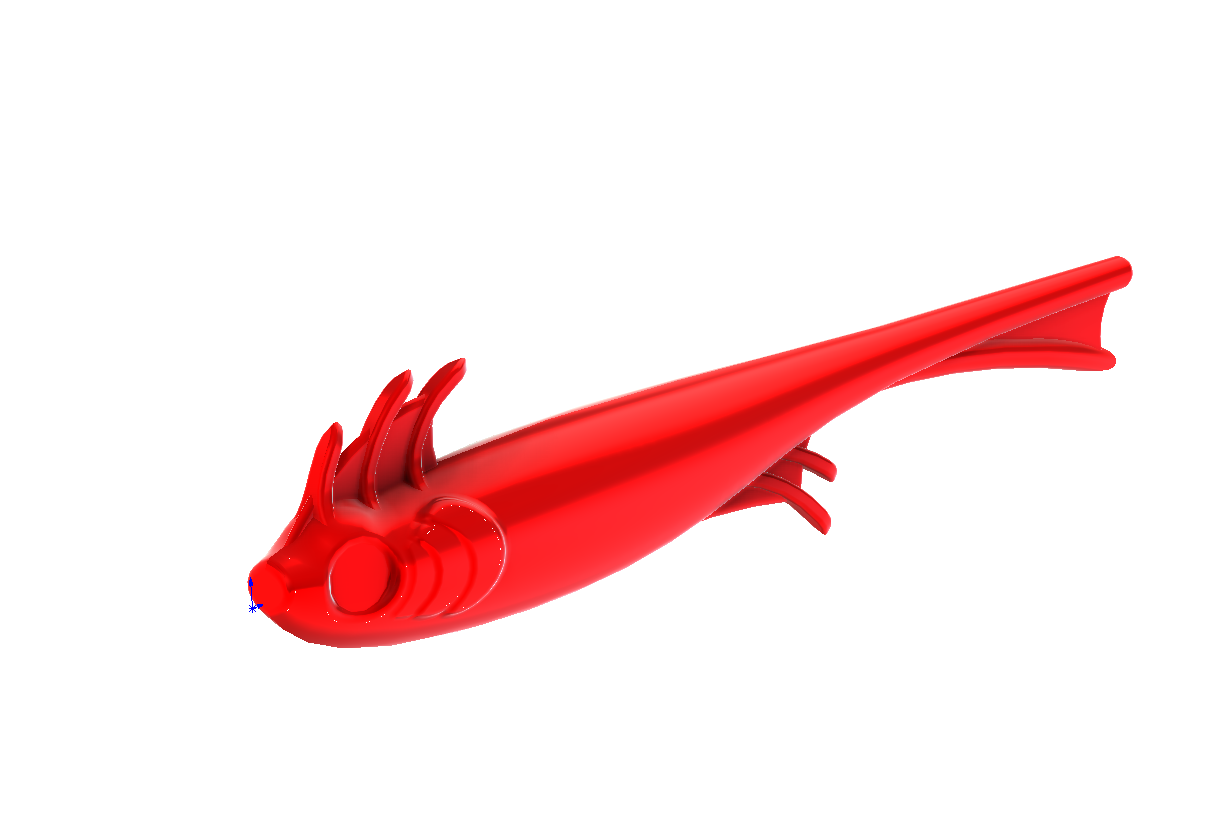

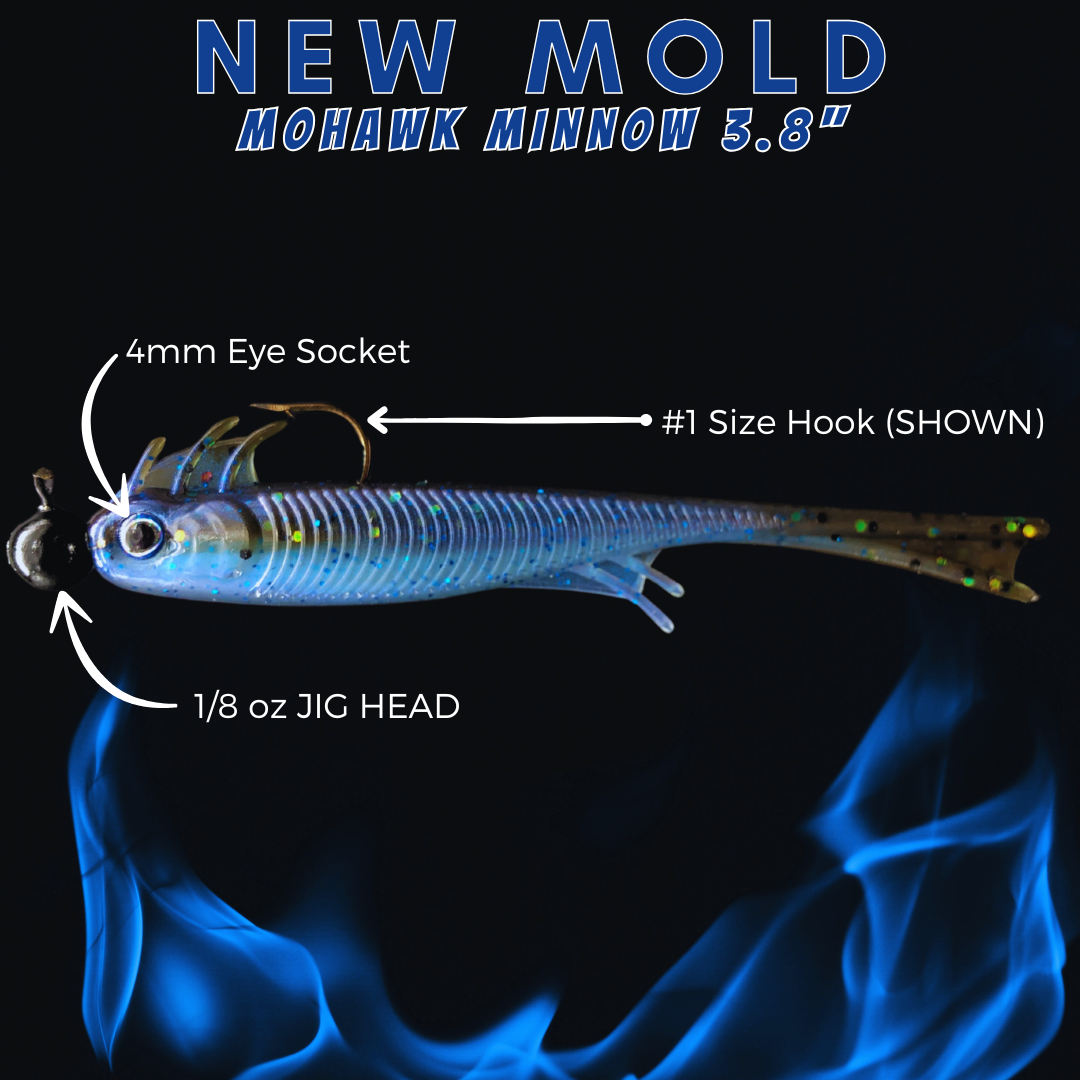

MOHAWK MINNOW 3.8"

MOHAWK MINNOW 3.8"

Couldn't load pickup availability

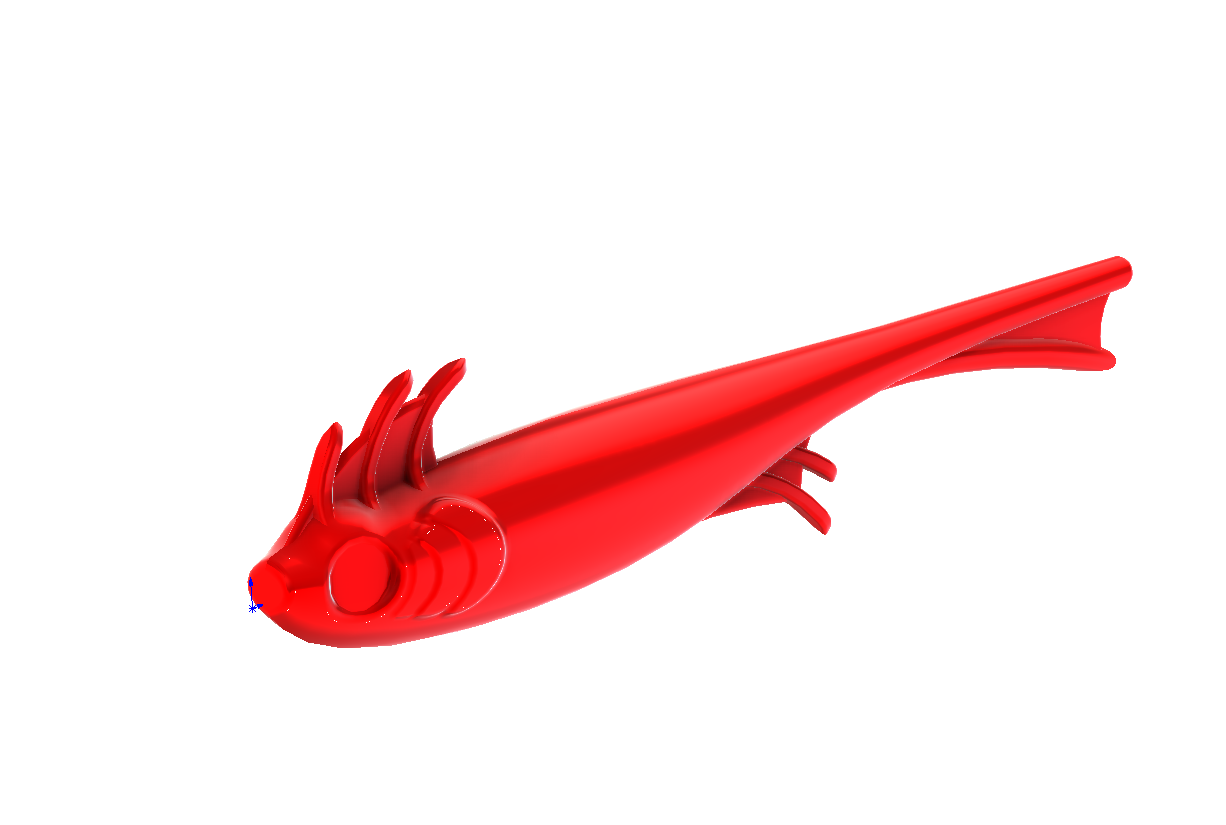

Mohawk Minnow 3.8" Mold – Craft Your Own Precision Minnow

The Mohawk Minnow 3.8" Mold is built for bait makers who take pride in crafting high-performance soft plastics with real-world action. This precision CNC-machined aluminum mold produces a 3.8” minnow with a streamlined baitfish profile and refined body details that trigger strikes.

The bait features a subtle washboard-style body for just the right amount of flash and water displacement—perfect for both stained and clear water conditions. A raised, flexible Mohawk ridge runs along the top of the head, allowing your jig hook to tuck cleanly behind it for a more natural and streamlined presentation. The Mohawk is designed to flex during hooksets so it won’t interfere with hookups.

The anal fin includes extended ribbing that flows into the body, creating additional movement and realism, while built-in eye sockets are perfectly sized to accept 4mm diameter eyes, adding that finishing touch for an ultra-realistic look.

- MADE IN THE USA!

- Produces 3.8” soft plastic minnow with sharp detail and consistent form

- Washboard-style body adds subtle vibration and flash

- Flexible Mohawk ridge offers hook concealment without sacrificing hookups

- Ribbed anal fin creates added turbulence and realism

- Eye sockets fit 4mm diameter eyes for easy customization

- Designed for ball head jigs (1/16 oz. to 1/4 oz.)

- Optimized for a #1 hook for proper alignment and performance

- Works with standard plastisol and injection systems

- CNC-machined aluminum for durable, smooth, repeatable pours

Rigging Options:

- Primarily for Ball Head Jigs (1/16 oz to 1/4 oz with a #1 size hook)

- Texas & Carolina Rigs

- Drop Shots

- Underspins & Small Chatter Baits

Tips for Preparation When Injecting

Follow these tips to get clean, professional results:

- Heat plastisol to 320°F – Ensures proper flow and mold fill.

- Inject using light, steady pressure – Prevents flashing and ensures clean cavity fill.

- Inject very slow and consistent to avoid air pockets or incomplete pours.

- Heat your blending block before laminating – Prevents gumming or plastisol freezing on the tip of the block.

***NOTE: When using powders or highlight powder for laminating, you may get some bleed over on the bait.***

For best laminate results: Make sure both colors of plastisol are between 300–315°F before injecting to ensure a clean, even bond between layers.